The Heat Response of CellTech Panels: A Deep Dive

CellTech panels are a standout choice for the ClimateRig™ cool-down trailer due to their exceptional heat response, driven by a unique structural design. These panels feature a honeycomb core made from hot-dipped galvanized steel, sandwiched between 80 ksi hot-dipped galvanized steel skins. The skins are coated with an anti-corrosion primer and a poly topcoat, enhancing durability and slightly tweaking thermal behavior. However, it’s the interplay between the core and skins that defines their superior insulation, making them ideal for combating heat stress in outdoor work environments.

How CellTech Panels Respond to Heat

To understand why these panels excel, let’s break down their heat response step-by-step:

1. Exterior Skin: Initial Heat Interaction

- When exposed to high outdoor temperatures (e.g., direct sunlight reaching 50°C or 122°F), the outer steel skin absorbs some heat. Steel naturally has a high thermal conductivity (~50 W/m·K), meaning it can transfer heat quickly.

- However, the poly topcoat acts as a reflective layer, reducing heat absorption by bouncing back a portion of solar radiation. This minimizes the initial heat load compared to uncoated metal surfaces.

- The skin is thin, so while it heats up, it doesn’t store much thermal energy, limiting the amount passed inward.

2. Honeycomb Core: The Insulation Powerhouse

- The magic happens in the honeycomb core, a lattice of hexagonal cells filled with air. Air is a poor conductor of heat, with a thermal conductivity of just 0.026 W/m·K—nearly 2,000 times lower than steel.

- These air pockets create a thermal break, drastically slowing heat conduction from the exterior skin to the interior. The trapped air doesn’t circulate freely (due to the small cell size), reducing convective heat transfer as well.

- For a typical CellTech panel thickness of 7.94 mm, the core dominates the panel’s thermal resistance. The effective R-value (thermal resistance) can be estimated at approximately 0.17 m²·K/W, though this varies slightly with core density and cell size. This is impressive for such a thin, lightweight material.

3. Interior Skin: Maintaining a Cool Barrier

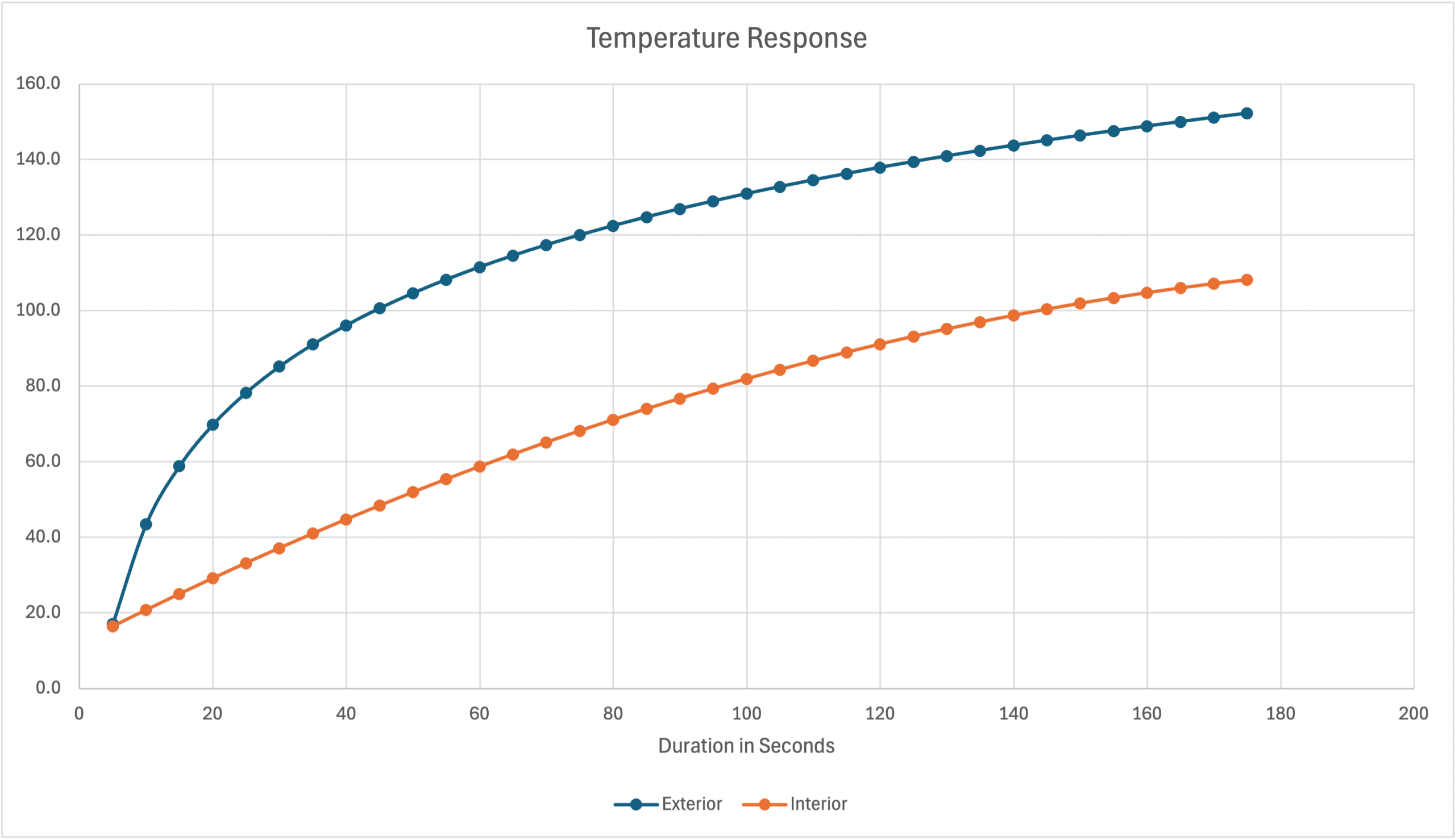

- By the time heat reaches the inner steel skin, its intensity is significantly reduced. The interior skin remains much cooler than the exterior, often by 20–30°C (36–54°F), depending on external conditions and the trailer’s air conditioning.

- The inner skin’s low temperature ensures that the ClimateRig’s interior stays comfortable, even as the outside bakes under the sun.

Heat Transfer Dynamics

- Conduction: Minimized by the air-filled core, which interrupts the direct path of heat flow.

- Convection: Negligible within the core due to the static air pockets.

- Radiation: Reduced by the reflective poly topcoat and the core’s ability to block infrared transmission.

In practical terms, if the exterior hits 40°C (104°F), the interior skin might stay below 25°C (77°F) with air conditioning, thanks to the panels’ ability to resist heat penetration.

Detailed Thermal Properties

Let’s dive deeper into the specific attributes that make CellTech panels exceptional:

- Low Thermal Conductivity

- The honeycomb core’s reliance on air as an insulator is key. Solid steel conducts heat rapidly, but the air trapped in the cells creates a barrier that heat struggles to cross. This is quantified by the core’s effective thermal conductivity, which is closer to air’s 0.026 W/m·K than steel’s 50 W/m·K.

- High Thermal Resistance (R-Value)

- The R-value is calculated as thickness divided by thermal conductivity (R = d/k). For a 7.94 mm (0.00794 m) panel with an effective conductivity of ~0.047 W/m·K (accounting for the steel skins’ minor contribution), the R-value is roughly 0.17 m²·K/W. This is competitive with thicker traditional insulators like foam, but in a much slimmer profile.

- Thermal Mass and Response Time

- The panels have low thermal mass due to their thin steel skins and airy core. This means they don’t retain heat for long, allowing the trailer to cool down quickly once the air conditioners kick in—a critical factor for workers needing immediate relief.

- Coating Effects

- The poly topcoat and anti-corrosion primer add a subtle boost to insulation by reducing emissivity (the ability to emit heat inward) and enhancing reflectivity. While not the primary insulators, these coatings fine-tune the panels’ performance.

Why CellTech Panels’ Insulation Is Perfect for the ClimateRig

The inherent insulation of CellTech panels aligns perfectly with the ClimateRig’s mission: providing a mobile, efficient, and reliable cool-down space for workers facing heat stress. Here’s why they’re an ideal match:

1. Optimized for Efficient Cooling

- The high R-value means less heat enters the trailer, reducing the workload on the dual 15 BTU air conditioners. For example, if 500 W of heat would penetrate a standard metal wall under sunlight, the CellTech panels might cut that to 200 W, allowing the A/C units to cool the space faster and maintain a target temperature (e.g., 22°C or 72°F) with less energy—potentially saving 20–30% in power consumption.

2. Stable Interior Temperatures

- Outdoor temperatures can swing wildly (e.g., 30°C to 45°C daily), but the panels’ insulation dampens these fluctuations. The interior stays consistently cool, providing a predictable refuge. This stability is vital for workers recovering from heat exposure, as sudden temperature spikes could undermine their relief.

3. Rapid Heat Stress Relief

- The combination of low heat ingress and quick A/C response means workers stepping into the ClimateRig feel relief almost immediately. Studies suggest that lowering body temperature within 15–30 minutes is critical for preventing heat stroke—CellTech panels make this possible by keeping the baseline interior temperature low.

4. Durability Meets Insulation

- Unlike foam-based insulators that might degrade under UV exposure or high heat, the all-metal construction of CellTech panels thrives in harsh conditions. The galvanized steel resists corrosion and warping, ensuring the insulation remains effective year after year, even in extreme climates like deserts or tropical zones.

5. Lightweight Efficiency

- The honeycomb structure offers a high strength-to-weight ratio, keeping the trailer light enough to tow easily (critical for mobility across worksites) while delivering insulation that rivals heavier materials. This balance is rare—most insulators add bulk, but CellTech panels don’t compromise portability.

6. Safety in High-Heat Environments

- The steel construction and fire-retardant polycarb twin sheeting windows ensure the trailer is safe in environments where heat stress often pairs with fire risks (e.g., construction sites with welding). The panels won’t off-gas toxic fumes or melt, unlike some synthetic insulators.

Real-World Performance

Imagine a construction site at 38°C (100°F) with workers in heavy gear. Without intervention, heat exhaustion sets in within hours. The ClimateRig, clad in CellTech panels, maintains an interior of 23°C (73°F):

- Heat Transfer Reduction: The panels cut heat influx by 60–70% compared to standard metal walls.

- Cooling Time: The interior drops from ambient to comfortable in under 15 minutes with A/C running.

- Worker Recovery: Workers can rest for 20–30 minutes and return refreshed, not just surviving but thriving.

Conclusion

The heat response of CellTech panels—driven by their air-trapping honeycomb core, reflective coatings, and high R-value—makes them a game-changer for the ClimateRig cool-down trailer. They don’t just insulate; they create a thermal fortress that’s lightweight, durable, and perfectly suited for protecting workers from heat stress. Whether it’s rapid cooling, stable temperatures, or long-term reliability, CellTech panels deliver exactly what outdoor workforces need in the fight against heat-related injuries.

About the author : Stephen

Stephen Allred is a dynamic and accomplished executive with over 20 years of experience in sales and marketing, currently serving as the CMO and CTO of ATS. Renowned for his ability to craft highly effective marketing campaigns, he drives business growth through cutting-edge technology and a results-oriented approach, focusing on high-impact strategies that align with corporate goals while steering clear of ego-driven pursuits. With a deep understanding of customer behavior, Stephen creates compelling campaigns that resonate with consumers, underpinned by the discipline to prioritize the most critical tasks. Boasting over 25 years of management experience, he is a committed leader dedicated to assembling talented teams and unlocking their potential to achieve ambitious objectives. As an adept strategist, he draws on an extensive study of both modern thought leaders and historical figures like Clausewitz and Sun Tzu to devise plans that propel corporate success. A champion of continual learning, Stephen stays ahead of industry trends and fosters a culture of innovation, encouraging his team to think creatively and embrace calculated risks. He graduated Magna Cum Laude from Utah Valley University with a Bachelor’s degree in Finance, where his exceptional performance earned him the prestigious “Outstanding Student Award.”